One of the types of pumps available in the market is the circulator pump, which is offered in the market with two different body materials. The body of one of the models of this pump is made of cast iron and the other has a steel body. These pumps are considered as part of centrifugal pumps. This pump is mostly used to circulate water. If you are planning to buy a hot water return pump, join us to answer all your questions and ambiguities in this regard.

How the circulator pump works

All centrifugal pumps have a blade called a propeller, which is constantly spinning due to the motor inside the spiral chamber. Water enters the pump through the suction port of the pump as well as from the middle of these impellers and our space between the vanes.

If the pump is on, this water in the space between the blades rotates with the help of a finned wheel. After the pump starts to receive kinetic energy by these impellers, it moves to the outer space of the impeller due to the escape force. Finally, water moves outward from the edges of the impeller.

Application of circulator pump

Circulator pumps are especially popular among consumers due to their many applications. In this regard, various companies, including Leo and Grandfoss, have produced and designed this product. In Iran, Abrvan Company is one of the leading manufacturers in the field of industrial pumps.

One of the main and most basic tasks of circulating pumps is to compensate for the reduction of frictional pressure of water flow inside pipes, fittings and coils used in closed heating and cooling systems. These pumps are also used in cases where the reverse return piping design has been done in large buildings. The pumps in this section have the task of providing the possibility of access to the lowest power and power required for uniform distribution of water flow in pipes and fittings and valves in all cooling and heating systems.

These pumps have different industrial and domestic applications. The main application of these pumps is in moving fluids with a minimum temperature of minus 10 and a maximum of 130 ° C. Other applications of these pumps are as follows for you:

- Consumption hot water return pump: The reasons for using this type is that the hot water should always be circulated in the pipes and inside the tank at the closest possible and most accessible position. The circulator pump is also called the hot water return pump.

- Boiler water circulation pump: The pump used in hot water systems and home and central heating systems is called boiler water circulation pump.

- Hot water pump: If coil sources or heat exchangers are used to supply hot water, separate pumps such as hot water pumps should be used separately to circulate hot water.

Types of circulator pumps

Hot water return pumps can be divided into the following two categories:

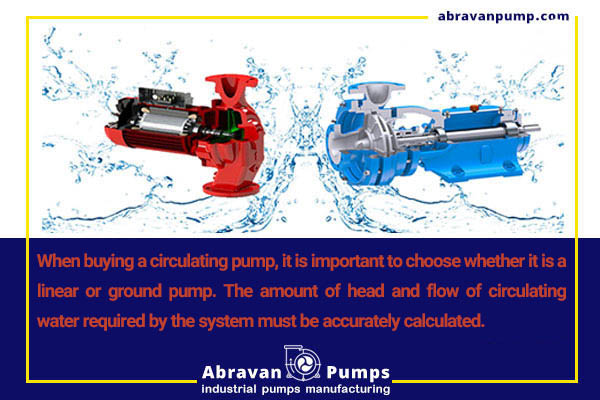

Linear circulating pump

These types of circulator pumps that are connected to the circuit are available in different types, such as: single or twin circulating pumps and single-cycle circuits. Its body is mainly made of cast iron and the impeller inside this type of pump is made of polyamide. These butterflies have anti-rust properties.

Ground circulating pump

Large and heavy pumps and electric pumps should be used when the capacity of use is high and more. Because the circuit cannot bear all this weight, it is placed on a chassis and on the ground. Vibration dampers are also used to reduce vibrations. These pumps are also called ground circulating pump or suction from the bottom.

These types of pumps are mainly made of cast iron. The impeller inside these pumps is also made of brass or cast iron. These pumps themselves consist of two types of electric pumps and etablocks, both of which differ in location and use.

Important points when buying

When choosing and buying industrial pumps, there are items and factors that should be considered and paid attention. When buying a circulating pump, it is important to choose whether it is a linear or ground pump. The amount of head and flow of circulating water required by the system must be accurately calculated.

Care in choosing the brand and model of this pump according to the required project is also very important. One of the advantages of Abravan brand is that all pumps of the company have 18 months warranty and 10 years after-sales service. You should also choose the right power and engine speed according to your usage. Do not forget to choose the correct diameter of the outlet and inlet pipes of the circulating pump. In the following, you will get acquainted with the said cases in detail.

Technical Specifications

Before buying and choosing these pumps, according to your application, you should check its technical specifications. That way, if you plan to use these pumps in small buildings, you should not use a 2900 rpm circulator pump. Circulating pumps with 2900 rpm motor have a high vibration sound and deprive the residents of comfort.

Pump Head

Gravity and natural flow of water inside vertical pipes, heating and cooling systems is one of the main and most determining parameters in the accurate calculation of the pressure required for the circulator pump and head. To calculate the pump head of cooling towers, even though part of the water path is open and due to the gravity flow in the return path of water into the condenser, the same method and formula can be used to calculate the Circulator pump head. The total head is calculated by the following formula:

Total head = height difference between two points 1 and 2 + pressure drop due to fluid transfer in the pipe + pressure drop due to connections and valves + required pressure or height at the point

The appropriate pressure drop rate for the water flow in the pipes for a circulating pump is calculated to be 300 milli inches per foot or two and a half feet per 100 lengths of pipe equivalent.

flow calculation

Calculation of circulator pump flow is different in heating and cooling systems. The following formulas can be used to calculate the diameter of the pipes and the flow of the circulator pump required in the heating and cooling systems:

In cooling systems, by dividing the kcal of each section on 1250 flow and the volume of circulating water in the same section, the cooling system is obtained.

Kcal / 1250 = BTU / 10000 = GPM

In each section of the heating system, by dividing kcal on 2500, the amount of flow or the same volume of circulating water in the same section of the heating systems is calculated:

Kcal / 2500 = BTU / 10000 = GPM

Circulator pump components

Electromotors: Circuit pump electromotors are synchronous. The windings used for medium power of this device can be connected to single-phase electricity and in high power and power can be connected to three-phase electricity.

- Shaft or axis: Transmitting motion from the electric motor of the pumps to the pump impellers is one of the functions of these axes. On the shaft, a large bearing surface has been designed that rotates the shafts without the slightest lameness and with perfect precision.

- Bearings: These bearings, which have a bronze material, are used to keep the pump shafts level. These bearings are long enough and there is a groove for lubrication on them.

- Mechanical seal: The presence of this mechanical seal or felt bowl prevents water from penetrating into the bearings.

- Coupling: In linear pumps, the task of transferring motion from electric motors to the pump shafts is performed by these components.

Impeller: The impellers of these pumps are centrifugal and their material can be steel or plastic, cast iron, rubber, brass, etc.

Price

Circulation pumps have variable prices depending on the different models they have. The company’s goal has always been to maintain quality along with the production of cheap circulator pumps. Contact the company numbers to inquire about the price.

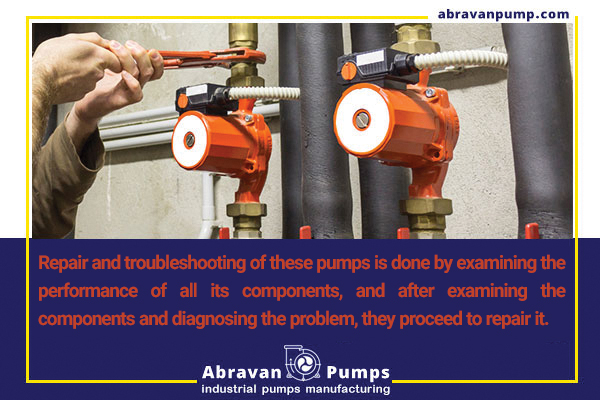

Circulator pump repair

Repair and troubleshooting of these pumps is done by examining the performance of all its components, and after examining the components and diagnosing the problem, they proceed to repair it. The specialists of Abrvan Company are ready to provide professional services in the field of circulator pump repairs.