Getting to know the hot oil pump (Hot Oil Pump). Buying guide with technical specifications

The hot oil pump is a type of centrifugal pump. Due to the special construction of this type of pump, it is capable of pumping hot oil from 300 to 350 degrees Celsius or water with a temperature of more than 185 degrees Celsius. The oil pump has a horizontal, one-story structure and a centrifugal single-suction spiral housing. If you are planning to buy a hot oil pump, stay with us to check this practical product further.

What you read in this article

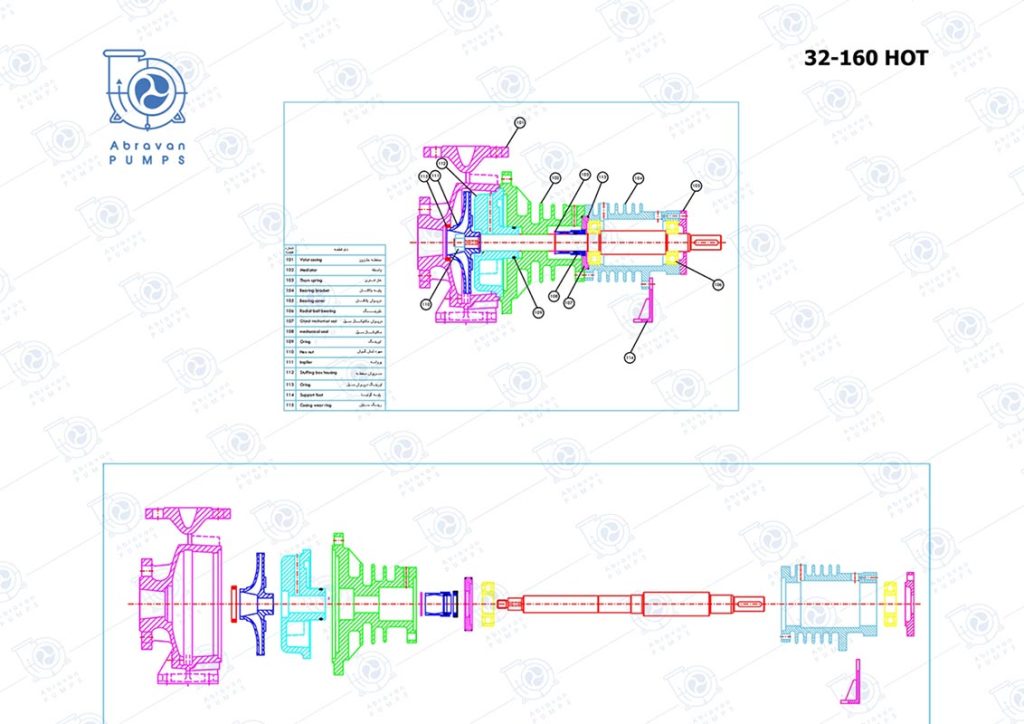

Technical specifications

From the hydraulic point of view, the impeller of the pump is balanced and is installed as a single and continuous suspension. In this type of pump, the bearing housing does not have a base, but the spiral housing has a base. The material of this pump is usually made of cast iron, which has high resistance to heat. The electric motor in this industrial pump is divided into two types of direct or indirect coupling.

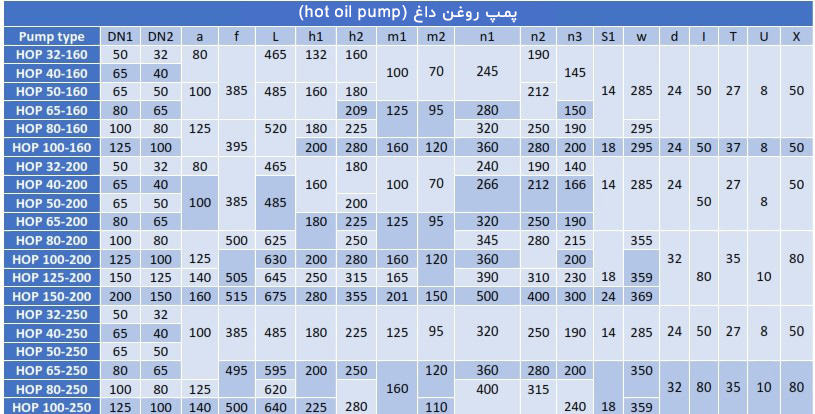

The speed of the electric motor in the hot oil pump, 1450rpm and 2900rpm, is selected according to the output flow and pressure. The shaft seal of this type of pump consists of two parts. In the chamber placed on the chamber cover, fireproof graphite tape is used to seal the axis, and a mechanical seal is installed at the end of the bearing chamber. In the table below, you can see the specifications of Abarvan oil pumps.

Application of hot oil pump

Hot oil pumps in different types, for industries such as: oil and gas, petrochemical, mining, machinery, paint, prefabricated concrete parts, heating systems in large buildings, in the food industry in baking ovens, cleaning systems Bottles, food frying systems, starch drying systems, are used in the oil and gas industry in power plants, crude oil production, in the production of solvents by evaporation method and heat exchangers.

Also in the metal industry in degreasing metal surfaces, in galvanic baths, in the textile industry for dryers, heating presses, in washing machines and irons, in the detergent production industry in soap making systems, dry Making raw materials and… Hot oil pump is used.

In general, the use of oil pumps in the following industries is summarized:

- Chemical and pharmaceutical

- food

- Plastic

- Textile, leather and paper

- color

- electric and steel and…

Oil pump in car engine

The oils inside the crankcase are sent to the engine parts and are lubricated under high pressure. This oil pump, which is driven by the crank, is also called oil pump or hot oil pump. In almost all engines, the power of the oil pump is prepared and supplied from the valve shaft.

Sometimes, the drive tooth is placed on the oil pump shaft and at the end of it, it moves the delco shaft as a coupling. Sometimes the drive tooth is located on the Delco shaft and the oil pump is powered by the coupling from the end of the Delco shaft. There are types of oil pumps that are attached to the engine body and can be removed when needed without opening the crankcase. For more information, we invite you to watch the video.

Generally, the oil pump is designed and installed in cars in two forms, gear pump or rotary oil pump. Oil gear pump has two gears, which are placed next to each other on two parallel axes. One of them is the driver and gets its movement from the pump shaft connected to the crankshaft. The drive gear rotates the idler gear, which is called the drive gear. With their rotation, the space between the ribs increases and the pressure decreases in a part of the pump.

The rotary oil pump is a more advanced model than the gear pump, and the air pump works much more. In this pump model, a rotor that is the driver is connected to the pump shaft and is called the internal rotor. The outer rotor, which is movable, rotates relative to the inner rotor.

How it works

In this pump, the desired liquid enters the pump impeller through the suction nozzle. The impeller rotates and with its rotation, the liquid moves between the holes in the radial direction towards the pump chamber. At this moment, a pressure drop is created and this condition causes liquid suction from the inlet. If the diameter and speed of the propeller is greater, the speed at the edge of the propeller is higher and as a result, more suction occurs.

How to start the hot oil pump?

After preparing this pump, it is necessary to ventilate it carefully. Open the caps on the top of the pump and pour the desired oil or liquid through one mesh cap until it comes out of the other cap. After this action, put both caps carefully and firmly in place to vent the hot oil pump.

After the pump starts working, the temperature of the liquid gradually increases until it reaches its highest level. After reaching the final temperature, you should turn off the pump and check the couplings. In general, at the first start-up, it is necessary to check all the parts carefully to make sure that they are healthy.